Advertisement

China is ready to make a key component for the world’s largest fusion reactor

- The international thermonuclear megaproject is aimed at producing an unlimited source of clean energy on Earth

- China’s contribution to global reactor project is an ‘unprecedented engineering effort’, expert says

Reading Time:3 minutes

Why you can trust SCMP

0

Ling Xinin Beijing

China has taken a major step towards a key contribution to an international mega-project aimed at creating energy through fusion – a potentially unlimited source of future energy.

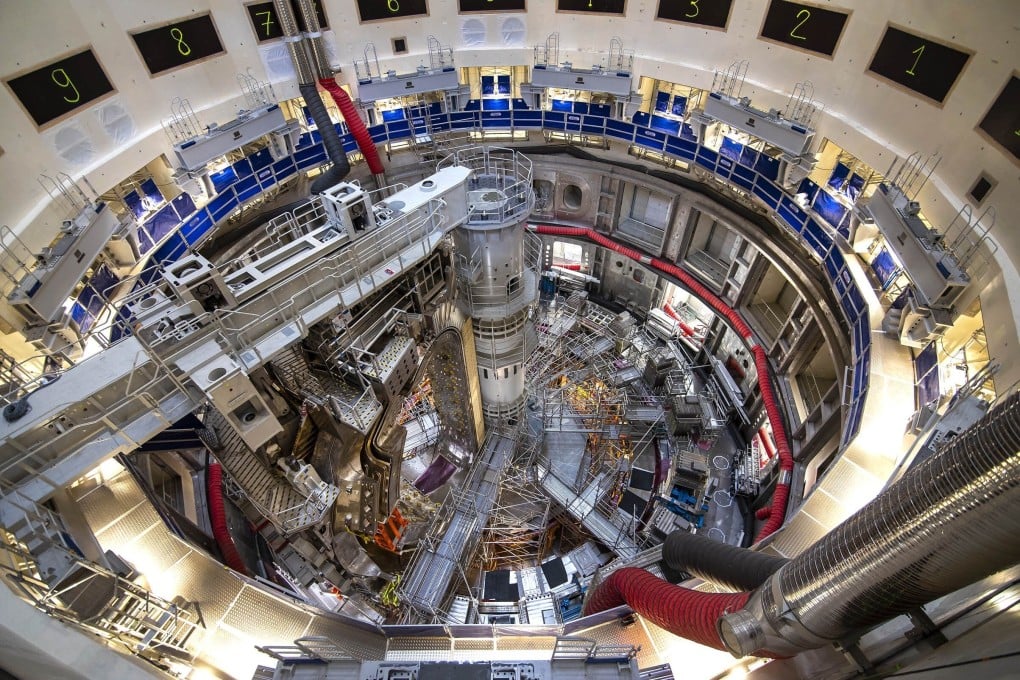

Scientists said they have successfully built and tested the first panel of an ultra-heat-resistant component for the International Thermonuclear Experimental Reactor (ITER), the world’s largest fusion reactor.

The components, which must endure super hot gas – known as plasma – up to 150 million degrees Celsius (270 million Fahrenheit) inside ITER’s doughnut-shaped chamber, “exceeded design performance and are ready for mass production,” its developer, the Southwestern Institute of Physics, said on Tuesday, according to the China National Nuclear Corporation.

The institute’s chief scientist, Chen Jiming, hailed the achievement as “a substantial breakthrough after thousands of experiments and 18 years of hard work”, and another example of China “fulfilling its commitments to ITER”.

China, one of seven members of the ITER project, is responsible for producing 54 of the 440 panels needed for the reactor. Together they will form the so-called “first wall”, a crucial part of ITER designed to protect the rest of the reactor by absorbing most of the radiation and heat from the plasma.

Advertisement