Behind the battery: how Porsche builds safer, longer-lasting EVs

As electric vehicle adoption surges in Southeast Asia, Porsche shows what sets its premium EVs apart from the crowd

Electric vehicles (EVs) are rapidly growing in popularity across Southeast Asia, transforming streets in cities such as Singapore, Kuala Lumpur and Bangkok. Supported by government incentives, expanding charging infrastructure and increasing environmental consciousness, EV sales in the region rose by nearly 50 per cent in 2024, according to the International Energy Agency (IEA).

As EV offerings increase, consumers are faced with more choice than ever. Many models share similar build aspects, such as a “skateboard” chassis, centrally mounted battery cells and electric motors positioned at the front or rear, so it can be difficult to distinguish one from another.

However, beneath these common design elements lie critical differences in engineering philosophy, battery durability and safety. These factors may not be immediately apparent in a brochure or a showroom test drive, yet they play a defining role in long-term ownership.

Porsche places great emphasis on these factors, which ultimately shape the reliability and safety of any EV. “Every high-voltage battery in a Porsche electric vehicle is tested for a service life of at least 15 years, and exceeding 300,000km [186,000 miles],” says Carlos Alberto Cordova Tineo, lead development engineer for HV Li-ion batteries at Porsche. “That far exceeds the usage profile of most customers and sets standards that we have not yet seen in the competition.”

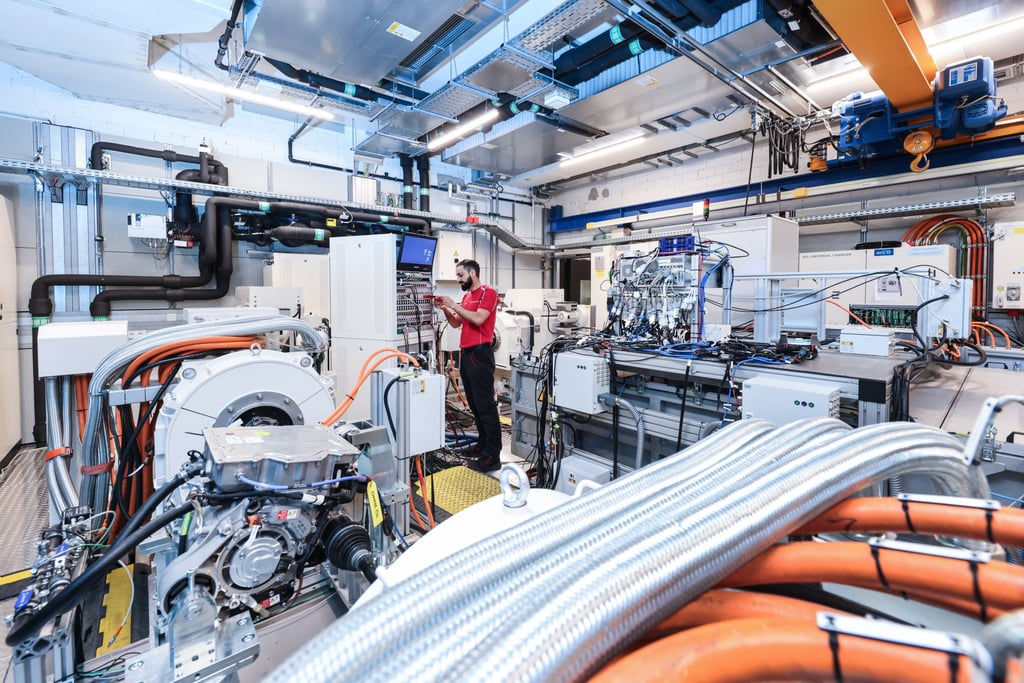

These durability claims are backed by an intensive testing programme at Porsche’s development centre in Weissach, Germany. Batteries are exposed to both typical and extreme use cases: high-speed driving, dynamic acceleration and long-term storage at high temperatures. According to Tineo, Porsche designs its systems to withstand scenarios most drivers will never experience, ensuring these batteries deliver long-term performance across a wide range of conditions.

This emphasis on thermal regulation is particularly relevant in Southeast Asia, where daily temperatures often exceed 30 degrees Celsius (86 Fahrenheit). Without proper regulation, heat accelerates battery ageing, reduces charging efficiency and compromises range. Porsche’s battery systems use patented fast-charging technology, supported by a robust cell design and cooling plates engineered to stabilise temperature during both charging and operation. These safeguards become especially important during fast charging or when the vehicle is in slow-moving traffic.

Porsche’s battery management system (BMS) plays a central role in sustaining performance over time. It continuously adjusts control of current and voltage, and actively heats or cools the battery to optimise efficiency while protecting it from premature wear. “We know not every driver will always follow ideal charging guidelines, so we design our systems to accommodate real life, not just textbook scenarios,” Tineo says. For example, drivers who frequently use public fast chargers or leave their vehicle parked in the heat can rely on the BMS to keep the system operating within safe, efficient limits.

This is further supported by Porsche’s patented fast-charging technology, which actively controls ageing factors such as charging current, state of charge and thermal exposure. The system includes features such as Battery Care Mode, which caps charge levels at 80 per cent during long-term storage, and the Porsche Charging Planner, which preconditions the battery for optimal charging performance. These strategies are designed to extend battery life and maintain consistent performance over years of use.

Safety is also a major cornerstone of Porsche’s approach to battery development. Every high-voltage battery undergoes an extensive range of safety validations, including long-term exposure to salt water, immersion in one metre (3.3 feet) of water and resistance testing against high-pressure water jets and heavy impacts. As part of the manufacturer’s “misuse testing”, batteries are pushed beyond normal customer behaviour to ensure structural integrity and electrical isolation under extreme conditions.

Porsche EVs also undergo the same full-vehicle crash testing as their combustion-engine counterparts, with added protocols specific to electrical systems. These include early fault detection and the ability to isolate and discharge the high-voltage battery quickly after a serious collision. “These safeguards are designed to operate within milliseconds,” Tineo says. “They’re not just about meeting requirements, they’re about delivering peace of mind.”

Internal vehicle architecture also plays a role in ensuring battery safety. Porsche positions high-voltage components in areas least likely to be damaged in a collision, and reinforces load-bearing structures to redirect energy away from sensitive systems. These measures are supported by extensive digital simulations and physical component stress tests that go beyond what a vehicle would experience in a serious crash.

Newer technologies are also helping Porsche look ahead. Artificial intelligence (AI) is now embedded into both the development process and post-sale monitoring. In the lab, AI helps engineers detect irregular charge-balancing behaviour and predict how usage patterns affect degradation. In the field, a feature called preventive anomaly detection – first introduced with the new Porsche Macan EV – analyses real-time battery data, detects anomalies at the cell level and alerts drivers via the MyPorsche app.

These innovations reinforce Porsche’s broader philosophy: that its electric cars are not designed for short-term use, but for long service lives, delivering consistently high levels of performance, safety and reliability. “It’s about building a car that not only performs well today but also performs well 10 years from now and beyond,” Tineo says. “That means less capacity loss, more consistent performance and fewer worries about battery replacement or residual value.”

This long-term thinking reflects a broader tradition at Porsche. According to the company, 70 per cent of all Porsche vehicles are still on the road today. Designed to last, these cars are passed down through generations – not just as performance machines, but part of a family’s legacy.

While many EVs may look similar on paper, Porsche’s development process reveals how engineering decisions around battery management, safety and durability can lead to fundamentally different outcomes, especially over the long run.