Curations: How Omega puts its Master Chronometer watches to the ultimate test of quality

- A 10-day process takes timepieces through a series of tests checking their performance in magnetic fields, underwater and amid changing temperatures

- The Swiss luxury brand’s certification was first applied to its Globemaster model in 2015, and it now defines a growing family of mechanical watches

Since the 19th century, Omega has remained in constant pursuit of precision in watchmaking and timekeeping, raising the bar time and again with new technologies, designs and practices.

The Master Chronometer standard reflects several horological achievements developed by Omega, including its Co-Axial escapement that operates with less friction, resulting in greater mechanical efficiency and long-lasting precision.

It also highlights the watchmaker’s success in conquering the effects of magnetism on timepieces. Magnetic fields are being constantly generated by electronics such as smartphones (380 gauss) and laptops (1,200 gauss), and can interfere with the functions of mechanical watches.

Omega solved this problem by developing a non-ferrous alloy called Nivagauss, which is used in its Co-Axial calibres along with a silicon balance spring. These materials give the brand’s anti-magnetic watches the ability to resist powerful magnetic fields of 15,000 gauss – the level typically generated by an MRI scanner – as well as sudden shocks.

In light of these innovations, Master Chronometer certification is only granted to Omega watches that are proven to function perfectly through various conditions of everyday wear while also demonstrating exceptional levels of magnetic resistance. This is determined through a series of eight stringent tests conducted on both the watch and movement over a 10-day period.

The eight tests have been approved and certified by Switzerland’s Federal Institute of Metrology (METAS), a government authority on measuring instruments and methodologies. But before that testing can begin, the movement must first be certified by Contrôle Officiel Suisse des Chronomètres (COSC), an institute that tests and verifies the precision of calibres made by Swiss watch brands. As a result, fulfilling the Master Chronometer requirements means double certification for the Omega timepieces.

Omega’s newest factory, located at the brand’s headquarters in Bienne, Switzerland, houses facilities and machinery for quality and technical testing in addition to the production assembly line. METAS also has offices there so it can oversee the testing process.

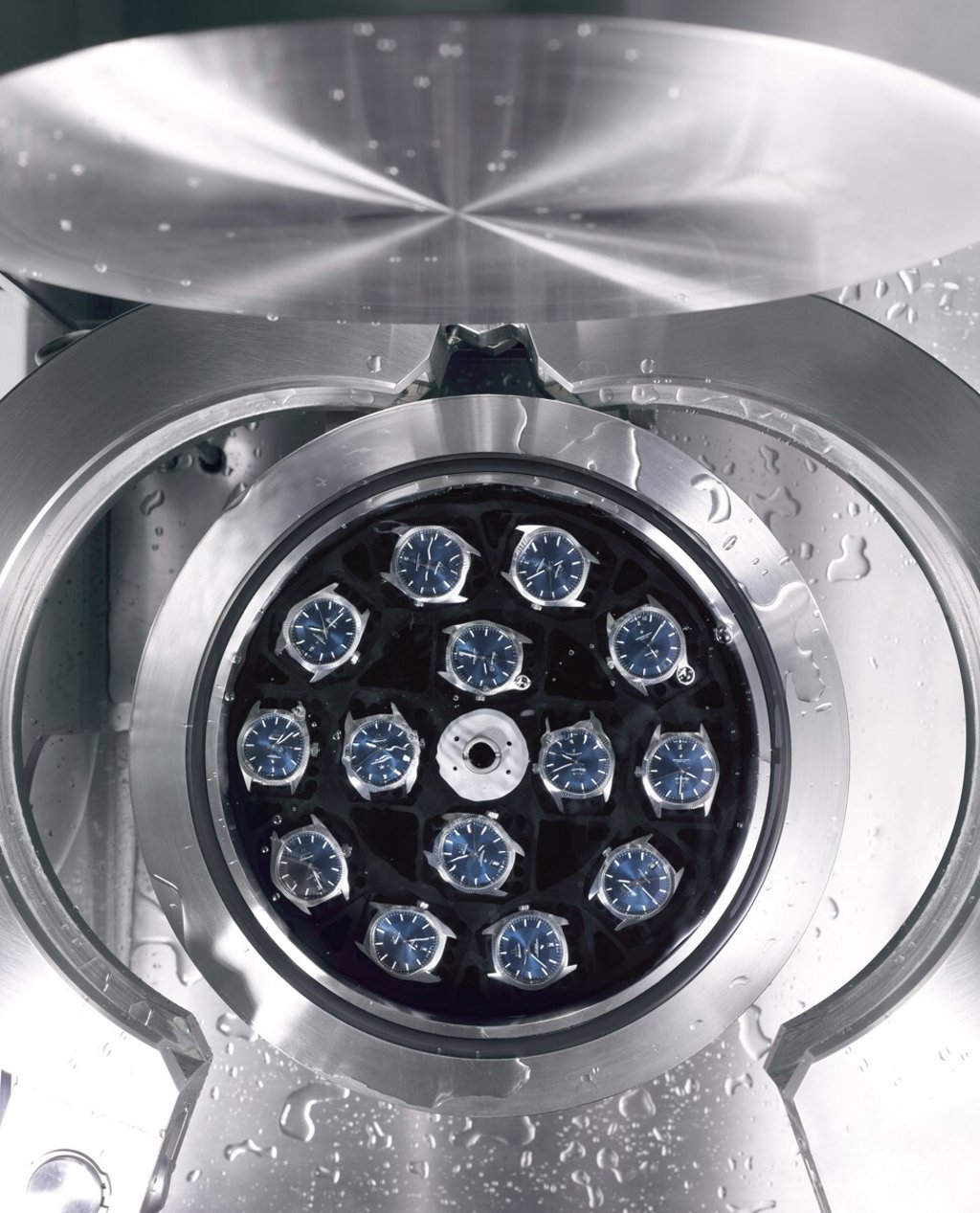

The series of Master Chronometer tests comprise a total of 283 steps, using purpose-built machines that operate 24/7 to put each watch through a thorough examination. During the first three tests, the movements and then the assembled watches are exposed to a magnetic field of 15,000 gauss, with microphones monitoring their ticking to confirm they are still functioning properly.

The third test is a two-day process that sees the watch magnetised in the 15,000-gauss field and its chronometric precision calculated after 24 hours. The timepiece is then demagnetised and the chronometric precision calculated again after 24 hours, with the minimal deviation between the two days serving as the recorded test result.

Watches are also tested for water resistance by submerging them in a tank, then gradually increasing the amount of water pressure inside. Another test applies different temperatures over four days and rotates the watches into various positions to see how their precision holds up through day-to-day use. At the end of the four-day test, the average daily chronometric precision is calculated for each watch to determine whether it passes the standard.

An important step during the series of Master Chronometer tests is to check the movement’s performance as the power reserve is drained. The watches are placed into six different positions, with their chronometric precision recorded at 100 per cent of the power reserve for each position. This process is repeated once the power reserve drops to 33 per cent. The average of the six measures at both levels of the power reserve are calculated to confirm that the deviation falls within the accepted range.

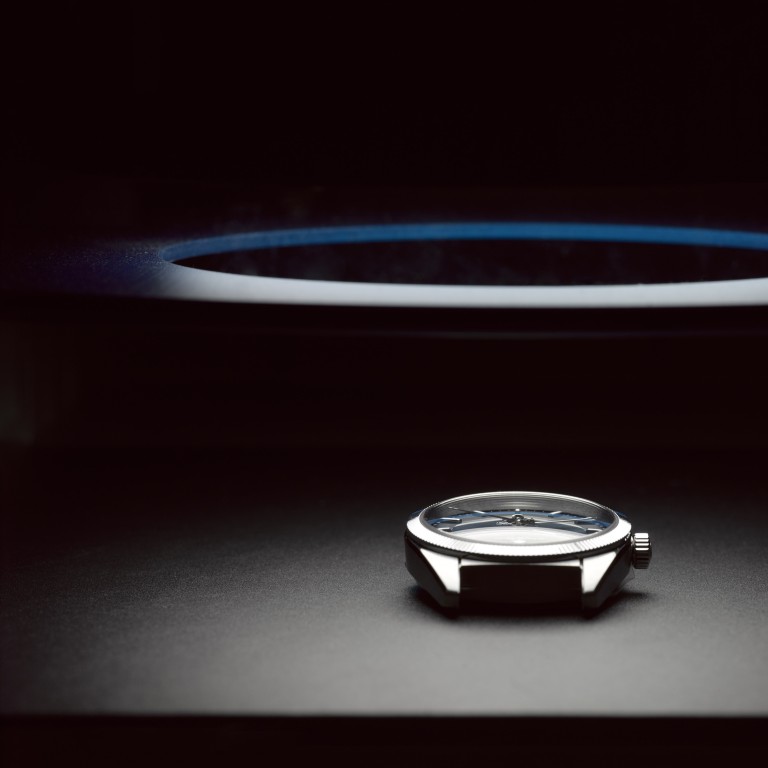

After a watch passes all eight tests, it emerges from the factory as a Master Chronometer timepiece.

The title applies to a growing family of Omega watch models. The Globemaster became the brand’s first Master Chronometer watch when the certification was introduced in 2015, and today it shares the standard with other popular models such as those in the Seamaster Aqua Terra collection, the Constellation Manhattan and the Seamaster Diver 300M Chronograph.

While Omega’s Master Chronometer models have the look of classic timepieces, they are paving the way towards the future of horology.