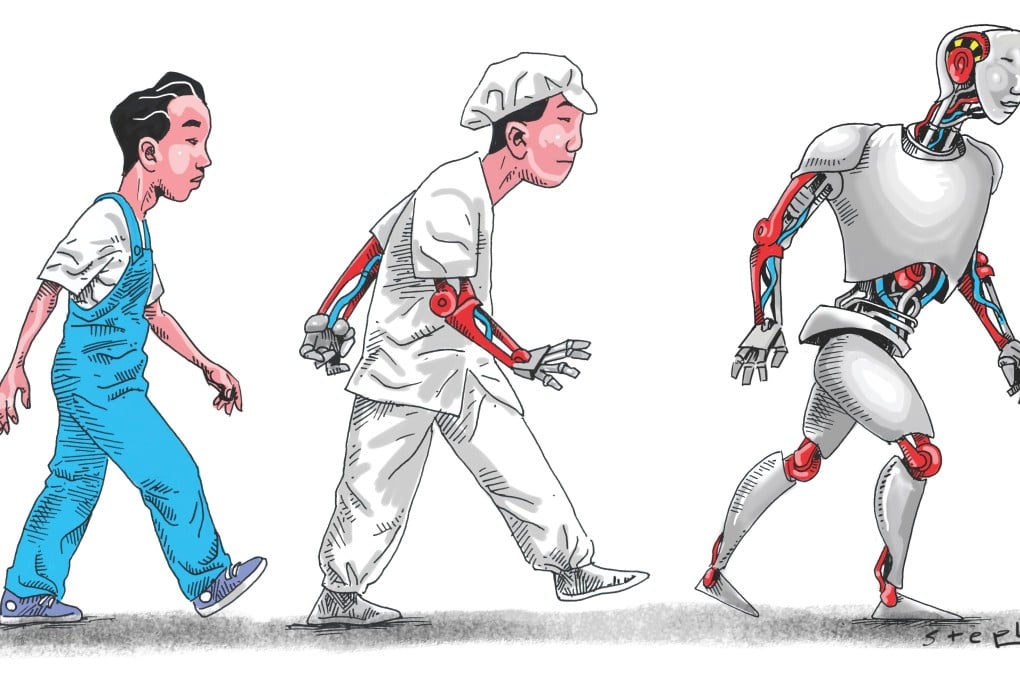

Chinese manufacturing seeks a major upgrade - through the use of robots

Thomas Roemer says there are good reasons for China's robotics push, not least its vision for the future

When Chinese officials recently announced plans to support investment in robots in China's manufacturing industries, the reaction in some US circles was one of astonishment, if not incredulity. Much of China's attraction as a manufacturing powerhouse, after all, has been low labour costs, so turning towards robots would seem like relinquishing a key competitive advantage. In fact, several key drivers explain why this is a very intentional and strategic move.

One key factor is that while China's labour costs still lag behind those in other key economies, Chinese labour has become relatively expensive compared to nations such as Vietnam and Indonesia. Moreover, Chinese labour costs are increasing at a much faster rate than in the US and, while the gap is still considerable, it is narrowing at a relentless pace. China also faces a labour scarcity in its economic boom centres.

The nation's one-child policy has had an impact, especially on the pool of available young factory workers and there are limitations on increasing the number of workers moving eastward from the western provinces. The competition for skilled labour is fierce, with attrition rates of 30 per cent or more per year not uncommon. Many companies report that fewer than 70 per cent of their employees return to work after the Lunar New Year. One US manufacturer estimates that 120,000 employees enter and exit its Chinese supply chain every week.

Allegations of inhumane working conditions are another reason to embrace robots. Robots cause no such concerns. They come to work every day, they don't unionise, they don't care about the Lunar New Year and, if needed, they work 24-hour days.

As collaborative robots can work next to and hand in hand with humans, they also eliminate the need for expensive safety cages or other safety measures. This helps explain why Foxconn plans to replace part of its 1.3 million workers with "foxbots".

Even better, robots get more skilled and cheaper year after year. Indeed, costs have been decreasing at an astonishing pace. According to a recent study by the Boston Consulting Group, costs for robots have decreased by more than 20 per cent in the past decade, a trend that is expected to continue during the next decade. Rethink Robotics' collaborative robots Baxter and Sawyer now cost well below US$50,000, which is frequently considered the threshold for a one-year payback time.